Applications

Discover our Applications

KULI offers various applications for your individual requirements.

Read more about the KULI applications below.

Designing a good cooling system is a very important part during the development of a vehicle. The necessary workload starts very early and continues throughout the development process. KULI enables the required simulation work in all these phases.

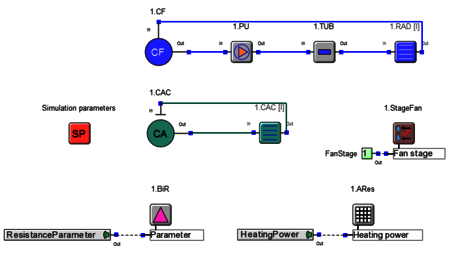

In an early development stage of a vehicle a first dimensioning of the cooling system must be done. In this phase typically a few steady state operating points – characterized by heat load, inlet and ambient temperatures and maximum allowable temperatures – are given that represent critical conditions for the cooling package. The corresponding KULI models are quite easy to set up and allow a very quick analysis of different radiators cores, radiator sizes, cooling package arrangements, fan rpms, etc. It can e.g. easily be determined which air flow is required such that sufficient cooling can be guaranteed. This information is essential for the design and aerodynamics departments. In this early development phase OEMs often provide the boundary conditions mentioned above to their cooling system suppliers in order to receive a proposal for a suitable cooling package. The suppliers can use the KULI optimization, parameter variation, and COM interface to automate the process of reading the boundary conditions, find the best package and provide a report of the results to the OEM.

In later stages of cooling system development the fluid side of the cooling system will also be modeled in more detail such that the distribution of the heat among the various components (heat sources and sinks, heat exchangers) can be simulated with high accuracy. With the help of the KULI signal path a control strategy can easily be included such that thermostats, pumps, valves, fans can be optimized to ensure sufficient cooling with lowest energy requirement. This is particularly important for hybrid and electric vehicles and for transient simulation in general.

To identify the temperatures in different zones of the passenger cabin the workflow to setup the KULI system is shown.

In a transient simulation the influence of the HVAC system in a cool down simulation in summer or heat up simulation in winter is performed.

Target

Determination of component influences to temperatures in the head and foot area of the driver and passengers (1st and 2nd row) based on A/C circuit performance and different air flow situations within the passenger compartment (fresh air, recirculated air, defrost or idle conditions).

Workflow for a typical cool down simulation

1st set up of an engine cooling circuit

2nd extend model with an A/C circuit

3rd add adjusted passenger compartment

4th Show temperature distribution inside the passenger compartment

One possibility to reduce energy consumption of EVs in winter is to use alternative heat sources for cabin heating. Sunamp uses latent heat storage “thermal batteries” for this task… different phase change material (PCM) melting points allow usage for heating and cooling. In this project we investigated potentials for PCMs supporting heat pumps. We also investigated how annual energy consumption is influenced in different global locations. In cold climates (e.g. Toronto or Berlin) even moderately sized PCMs allow saving more than 40% of heating energy compared to PTC-only scenarios… and more than 15% compared to conventional heat pump systems

EV range reduction due to HVAC System energy consumption is a big issue, especially in winter. Passenger comfort is a huge topic in summer, especially when both EV battery and passengers require cooling. As a big temperature delta between cabin and exterior is one driver for this, thermal insulation of the cabin can help. Honeywell has an insulation foam blowing agent technology for this task in their portfolio!

KULI complete vehicle VTM simulations (based on a calibrated baseline vehicle similar to Tesla Model S) show a range improvement potential of around 3.5% (warm-up) to 4.6% (continuous heating) at -10°C ambient temperature. In warm conditions (40°C ambient temperature) cool-down time from 60°C to 25°C can be reduced significantly by up to 50%.

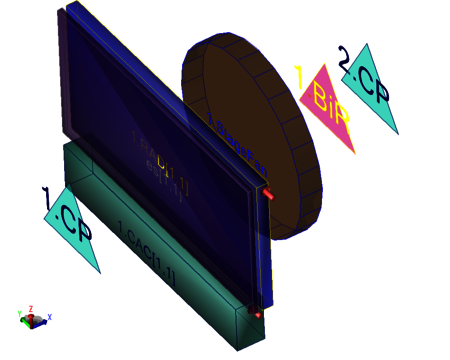

In later phases of the development of a cooling system, more information becomes available. Quite often CFD models of the underhood region provide detailed insight regarding the air flow. These CFD models already include the cooling package information from the initial cooling system design (see Initial cooling system). The typical approach is to perform isothermal CFD simulations and use the resulting mass flows to calibrate the 1D KULI model. Moreover the nonuniform velocity profiles on the radiator surfaces can be used by KULI using the CFD interface of KULI advanced cfd. The KULI model is used to calculate the temperatures and heat flows in the cooling package.

This information can then be used in CFD to update the 3D model. A dedicated porosity calculator ensures that the 1D KULI model and the 3D CFD model use the same resistance for the cooling package.

With KULI you can model cooling systems for railroad applications, which can be diesel or electrical powered. In this specific application you can find a roof mounted cooling system with three coolers. One low temperature circuit for cooling the electric and electronic parts, one high temperature radiator for engine cooling and one intercooler.

One can include different types of fans, hydrostatic, electric or mechanical driven. In the simulation one can control the speed of the fan very flexible depending on the requirements of the cooling system measured by sensors like in the real life. Of course the operating conditions e.g. driving up a high mountain or in hot climate conditions are considered in the cooling system simulation.

At the end of the various variants done in the concept phase to find the best configuration of all components one will get a virtual prototype of the whole cooling system for railroad applications, which you will produce only once in hardware to verify the KULI simulation results on the test bench and in build-in situation.

KULI allows comfortable generation of simulation models for electric vehicle cooling systems using the KULI battery model, KULI e-machine model and KULI power electronics models (DC/DC or DC/AC). Apart from general thermal management (e.g. cooling package design and layout) and energy management (e.g. investigation of thermal losses in the electric powertrain) topics, one main application is the prediction of the vehicle range.

Benefits

EV range varies strongly based on ambient conditions and related energy consumption of the HVAC system (heating in winter and cooling in summer). KULI can simulate all these effects by including the AC system and the KULI multi-zone cabin model into a complete vehicle simulation model. Apart from analyzing a baseline system this also allows the optimization of the thermal management for example by modifying the HVAC operating strategies.

Usage of the model

The range prediction sub-system provided in the enclosed example predicts the expected vehicle range over a user-defined drive cycle. The predicted range is calculated based on energy usage during the cycle and remaining usable battery charge. As the efficiency of the vehicle depends on the operating point, this value will change during the transient simulation. This allows not only evaluating the expected range after the complete cycle (e.g. NEDC) but also the identification of factors which influence the vehicle range in a positive or negative way.

This subsystem can be used in the context of the provided vehicle simulation model, but can also be exported and used in other similar applications without any problems.

The example provided for this application is also investigated in much detail during free of charge KULI thermal management workshops held several times each year at different worldwide locations.

One reason for EV range reduction in winter is the fact that usually vehicles have to run in fresh-air mode to prevent window fogging. GXC have developed a window coating, which causes humidity to condensate as a transparent film rather than opaque droplets (fogging). Accordingly much higher air recirculation rates are feasible (as also shown by tests done by GXC Coatings). But what is the resulting range benefit?

KULI complete vehicle VTM simulations (based on a calibrated baseline vehicle similar to Tesla Model S) show a range improvement potential of up to 11% in winter conditions (warm-up at -10°C ambient temperature).